Autonomous Battery-Swapping System — the headline feature

Walker S2 uses a dual-battery system (two 48-volt lithium battery modules) allowing one module to run while the other is being charged or swapped.

The robot is capable of autonomously replacing its own battery packs without human intervention or full shutdown. For example, a demonstration shows it walking to a battery bay, removing a spent pack and replacing it with a fresh one in about 3 minutes.

It also features real-time battery monitoring and the ability to decide whether to swap or charge based on task priority.

Watch Walker S2 swap its battery in 30 seconds:

So why is autonomous battery swapping a good thing?

Reduced downtime: Because it can swap battery modules autonomously, it potentially runs much longer without human intervention, making 24/7 operations more realistic.

Flexibility in scheduling: The robot can decide whether to charge or swap, aligning power management with task importance.

Redundancy & safety: The dual-battery system allows one battery to act as a backup in case of failure, and the design includes mechanisms for safe quick-swap under power.

Appealing for industrial adoption: For manufacturing or logistics operations where uptime is critical, this feature addresses one of the big pain-points (robot power/charging interruptions).

But it is not without problems:

Even with the swap system, the underlying runtime is still limited: one source reports ~2 hours of walking or ~4 hours of standing per battery module.

Charging a battery still takes significant time (e.g., ~90 minutes for full recharge) if no fresh pack is available.

Infrastructure requirement: The battery bay/station and swapping mechanism must be installed and integrated in the facility, which adds cost and complexity.

Reliability & scale: Autonomous battery swapping is demonstrated, but real-world long-term reliability (thousands of cycles, harsh factory environment) remains unproven publicly.

Cost-benefit trade-off: The added hardware/software for swapping may increase unit cost; for some tasks lower-cost robots might suffice without such features.

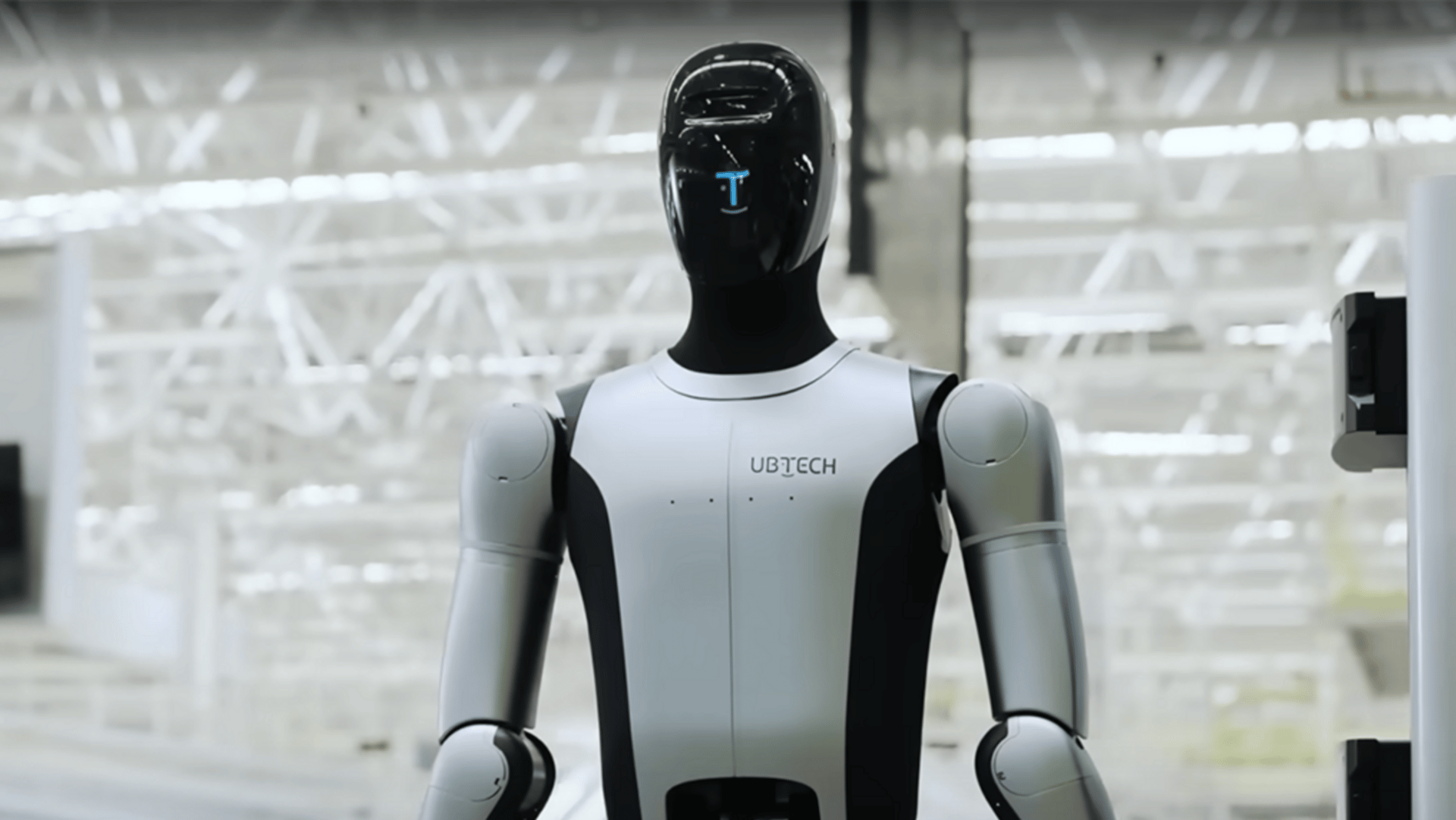

Other notable capabilities

Payload/manipulation: Walker S2 can handle up to ~15 kg payload within a workspace of 0-1.8 m and has a waist rotation up to ±162°.

Vision/perception: It uses a pure RGB binocular stereo vision system with deep-learning based stereo depth estimation to approximate “human-eye” stereoscopic perception.

Mobility/body: The robot features ~52 degrees of freedom in its bionic body, enabling human-like walking, squatting (pitch ~170°) and reaching.

AI/control: It is integrated into UBTECH’s “BrainNet 2.0 + Co-Agent” system for task planning, multi-robot coordination/swarm intelligence in production-line environments.

Want to read more like this?

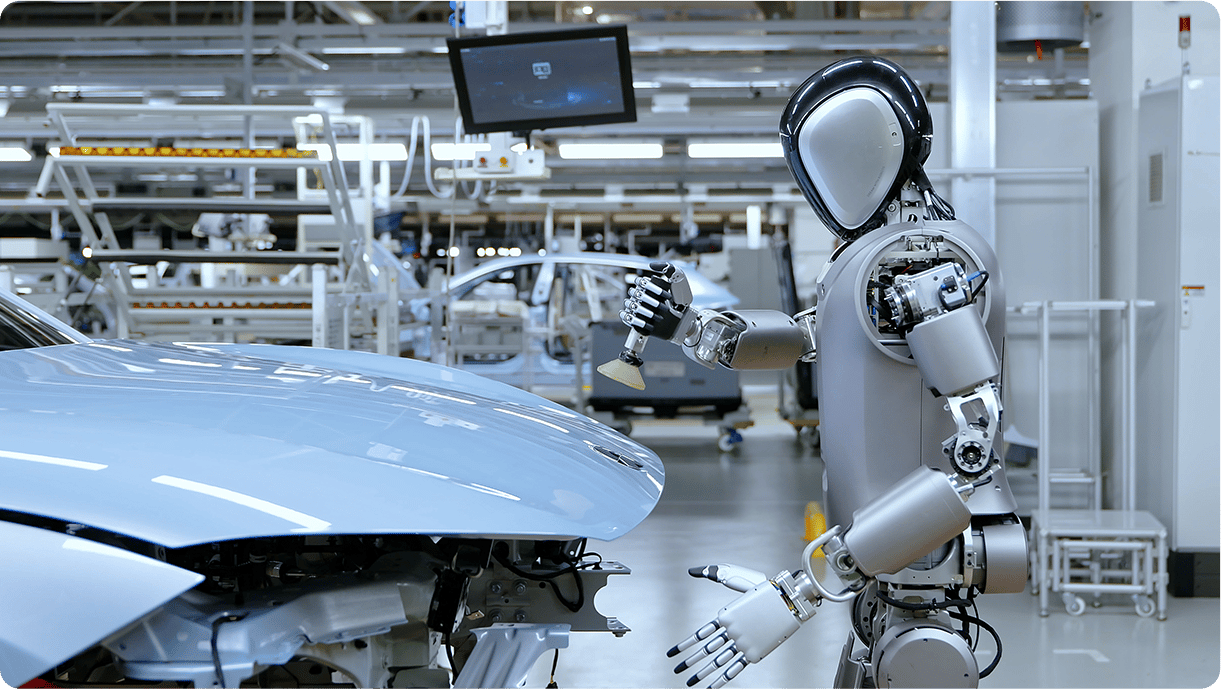

Known Deployment Cases

UBTECH states that the Walker S series is already used in multiple vehicle OEM production lines (automotive companies) worldwide. The company claims that the Walker S series is “deployed in more automotive factories than any other humanoid robot”. The company plans to deliver 500-1,000 units of Walker S series by end of 2025 for industrial customers (including automotive).

1. Zeekr (EV brand of Geely Auto) factory, Ningbo

Location: Ningbo, Zhejiang Province, China.

Deployment: Dozens of Walker S1 humanoid robots deployed in Zeekr 5G smart factory for multi-task, multi-scenario collaboration: sorting, handling, precision assembly.

Specific: One source says the Walker S Lite model (a lighter variant) worked at Zeekr for 21 consecutive days in a “training” context, carrying loads and collaborating with AGVs/AMRs.

Functions: Autonomous navigation (via VSLAM), end-to-end imitation learning, visual recognition, walking while carrying ~15 kg boxes.

Significance: Marked as “the first humanoid robot team” deployed in an automotive factory setting in China.

2. NIO Inc. factory (assembly/inspection)

Deployment: Walker S robots (by UBTECH) were deployed for training at a NIO factory (NEV assembly line) for tasks such as quality inspection of door locks, headlight covers, seat belts.

Status: Based on the video demonstration shared by UBTECH, the details suggest training/pilot phase rather than full production deployment.

3. Dongfeng Liuzhou Motor Co. (Automotive manufacturing)

Agreement: UBTECH inked a strategic cooperation agreement with Dongfeng Liuzhou Motor to introduce Walker S into their factory.

Tasks: Robot to perform inspection of seat belts, door locks, headlight covers, body quality, oil-filling, front‐axle packaging, material collection/picking, labeling.

Status: At least agreement and training phase; not confirmed full deployment scale.

4. BYD Company Limited factory (logistics integration)

Deployment: At BYD’s factory, the Walker S1 was part of a “full-stack unmanned logistics solution” — collaborating with AMRs/AGVs/industrial mobile robots and MES.

Tasks: Sorting, handling, distribution in indoor/outdoor logistics process.

Significance: Marks application of humanoid robot in the logistics segment within automotive manufacturing contexts.

Outlook

The battery-swapping capability of Walker S2 gives it a technically strong proposition: if indeed able to operate continuously with minimal intervention, it addresses a key barrier for humanoid robotics in industrial settings. However the real question is economics and scale: whether cost, reliability, integration and task-efficiency align to make it a viable replacement or supplement to existing industrial automation.

If UBTECH can scale deployment (hundreds to thousands of units) and demonstrate solid uptime/ROI in real factories, this feature could move humanoid robots closer to mainstream industrial use. On the flip side, if the runtime remains lower than claimed, if the infrastructure costs or maintenance burden are high, or if tasks cannot be economically justified, then the innovation may remain niche.